Our Services

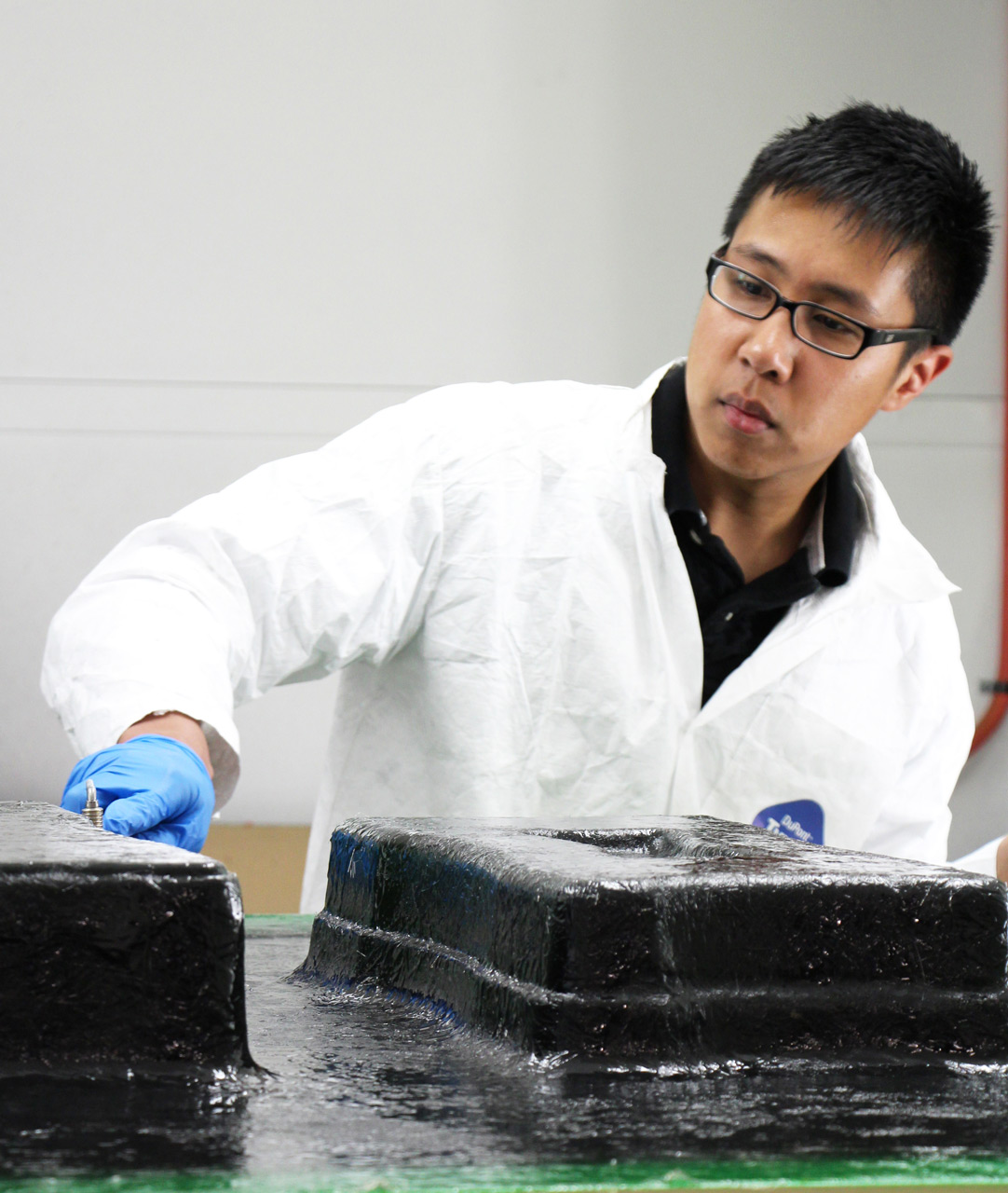

We’re a one-stop-shop and offer a variety of services that will help you take your concept for a project from the initial idea through to prototyping.

Below are the services we offer.

Design & Analysis

Our design team develops composite part designs, partnering with clients through each step of the process – from conceptual models, through prototyping parts, to production ready components. Our designs are developed by minimizing weight and cost while increasing performance and are always created with the manufacturing process in mind.

Watch The Video

Our Design Services Include:

- Computer Aided Design (CAD) modeling and drafting of composite, plastic and metallic parts

- Material and process selection using our material property database

- Laminate schedule development and optimization for weight, cost and performance

- Finite Element Analysis (FEA) – used to perform mechanical/structural, modal, and thermal analysis of composite structures

- Ply draping simulation – produces a flat pattern for production

- Tooling design for hand, RTM, RTM lite and infusion manufacturing processes

- Joining and bonding

- Failure analysis and repair

- Cost/feasibility analysis

-

For inquiries of how our design services, tools and processes can work for you and your organization, please contact:

Eugene Rothwell

eugene@ecopoxy.com